PATAN PATOLA, THE CLOTH OF KING

Two fluorescent bulbs cast harsh shadows on the peeling walls of the cramped workshop in Patan, a town in India’s Gujarat state. Eight workers sit inside, silently focused on the tasks at hand: carefully wrapping and unwrapping thousands of dyed silk threads.

A middle-aged man, Mr. Soni, stands at the center of it all, a master watching over his craftsmen. And watch he must: if one mistake is made, the process must begin all over again. Such is the art of Patola, India’s most complex textile.

PATOLA: CLOTH OF KING

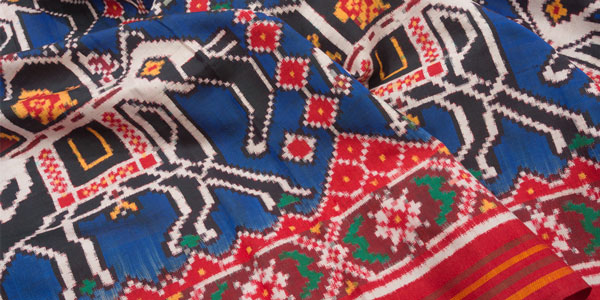

The complexity and time-intensiveness is what makes Patola so valuable. A dizzyingly mathematical process, Patola saris are woven using dyed threads both vertically (warp) and horizontally (weft) to create the design. The strings are dyed according to a pattern, and the dye marks align when woven, forming the pattern on the cloth.

For each color in the design, workers tie sections of the silk threads with cotton string until only the parts to be dyed remain exposed. The whole bundle of threads is then soaked in dye, before the cotton strings are torn off to reveal the un-dyed portions. Rinse, repeat, until the threads are all dyed to match the pattern.

The wrapping and dyeing process for just one color takes a week, and doing all the colors takes one or two months. Mr. Soni tell us how, from start to finish, designing and making one saree takes at least seven months.

Our jaws hit the floor, but it’s standard procedure for Mr. Soni. To put things in perspective, he tells us the most difficult sari they ever made took 2.5 years. But the price tag on a Patola sari justifies the days of painstaking work: one custom-made sari starts at 150,000 rupees, about $2,250.

After watching the workers nimbly tie and untie threads for half an hour, we’re chomping at the bit, excited to see everything come together in the weaving rooms. But Mr. Soni leads us away from the workshop instead.

He insists we make a quick stop before he reveals the rest of his workshop’s secrets. “It’s important, first, that you understand the story of Patola.”

PATOLA OF FUTURE

History lesson complete, we return to the workshop, where we’re treated to the sight of half-completed Patola in the making. Massive wooden looms fill more peeling workshops, vibrant silk threads crisscrossing otherwise threadbare rooms. Mr. Soni flits to and fro between the different looms, stopping to adjust some misaligned threads when he espies them. Whenever he does, the others often stop to watch the master at work.Unlike the Salvis, the Sonis open to teaching parts of the Patola-making process to those not native to Patan, so long as they are hard-working and willing. But potential masters are in much shorter supply. Finding someone competent enough to wrap their minds around the highly mathematical designing and dyeing process is no easy task, and so the father and son remain the gatekeepers of the knowledge. For now.

Harshil Raiyani

Harshil Raiyani